What does cyclone mean? Dust collectors used in industrial enterprises are called cyclones. These machines improve air quality by capturing dust particles in the environment. These devices, which function as filters, consist of three parts: dirty air inlet, clean gas outlet, and dust discharge system.

What does cyclone mean? Cyclones can be designed in different models and sizes. What determines the type of cyclone is the need of the area where it will be used. High-capacity cyclones can be produced for large-scale enterprises. Therefore, there is no optimum design for cyclones. Information about the technical specifications, dimensions, and prices of cyclones can be obtained by contacting the manufacturing companies.

The working principles of cyclone filters can be listed as follows:

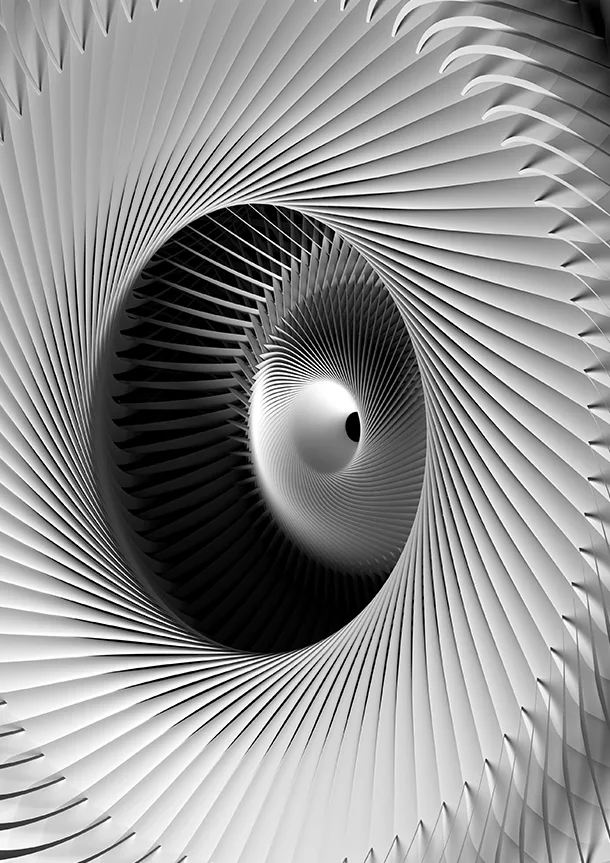

- It directs the air flow into the cyclone chamber, creating a vortex effect.

- Solid particles (dust, dirt, shavings) in the rotating air are pushed to the outer edges.

- Particles pushed to the sides are collected in the filter container.

- The continuing rotating air exits through the outlet channel, cleaned.

What Does Cyclone Filter Mean?

Cyclones, also known as dust collector filters, hold an important place among dust trapping technologies. These systems are designed to separate fine dust particles from the air stream. Cyclone filters are used in industrial applications and play a significant role in reducing air pollution. They are also preferred for their energy efficiency and low maintenance requirements.

Cyclone filters have a wide range of uses in industrial areas. Some of these areas are:

- Enterprises producing cement,

- Wood and metal processing plants,

- Mining,

- Chemical and food processing facilities,

- Power plants,

- Waste processing and recycling facilities,

- Feed factories and animal farms,

- Pharmaceutical industry.

Dust collector filter systems are fixed-part devices that draw in an air stream containing solid particles, transform it into a vortex motion, and separate the solid particles through centrifugal force, thereby purifying the air. There are various designs of cyclone filters. However, the most commonly used type of cyclone in gas cleaning is the one with tangential inlet, single cylinder, single cone, and axial outlet.

What Are the Benefits of Cyclone Filters?

There are many advantages of dust collector cyclone filters used in industrial areas. The first and most important is that cyclones make the work areas healthier and safer. This also ensures worker health and safety. In addition, these filters, which require minimal maintenance due to their simple design, reduce operating costs in the long run. Cyclone filters used in heavy industrial conditions are very durable and long-lasting. They can work effectively even in high temperatures and high pressure conditions.

Dust cyclones, which operate with low energy consumption and can be produced in different sizes and capacities, adapt to many industrial environments. Their installation is quite easy, and they can be integrated into existing systems. The use of a dust absorbing filter to clean particles that cause air pollution provides an environmentally friendly application.

In the absence of cyclone filters, various negatives can occur. These negatives are:

- Increased air pollution,

- Worker health and safety issues,

- Increased maintenance and repair costs,

- Decrease in product quality,

- Reduction in efficiency.

In the absence of dust collector cyclone filters, enterprises may encounter such problems. Therefore, it is recommended to use filtration systems, especially in industrial enterprises where dust and particle dispersion is intense.

For detailed information and to order cyclone filters, you can contact us.